1. Applications:

The TBQSe Quantometer is a turbine meter for operational natural gas volume measurement and for other non-aggressive gases such as propane, butane, air, carbon dioxide or inert gases used in interna and controlling processes of various types, especially in industrial therma processing facilities.

2. Features:

Meter size: G10 to G1600

Pressure class: PN 16 and ANSl150

Flow rates: From 2 to 2500 m³/h

Measuring range: 1:10 or 1:20

Nominal sizes: From DN25 (1'') to DN200 (8")

Meter body made of anodized high strength Aluminum

Maintenance free based on permanent lubrication of the ball bearings

Manual lubrication of the ball bearings by means of oil pump as option

Electronic index head standard made of Aluminum

Lithium battery with a calculated life time under standard conditions of 5 years, optional external power supply

Integral electronic volume corrector(AGA NX-19) and data storage as option

Connection of an cxtemal pressure and temperature measurement is possible

Communication options: serial RS 485 interface, Modbus. M-Bus, 4 to 20 mA output, high freguency or low frequency pulse output pressure and temperature inputs

Rotating index head (180°)

Arameterization via a PC based software (HMl)

Recommended straightinletpipe ≥3DN and outlet pipe ≥2DN

Horizontal and vertical mounting position

Approval according to PED (PED2014/68/EU)

ATEX /IECEx Ex-Zone 1; Ex ia ll C T4Ga

3. Operation Principle:

The TBQSe Quantometer is a turbine gas meter that registers the operating volume using a nine-digit electronic index. The flow of the gas to be measured causes the turbine rotor to rotate. The gas flow is narrowed on an annular cross section, is accelerated and directed onto the smooth-running aluminum rotor, The number of rotations is proportional to the measured gas volume: the

frequency of rotations is proportional to the actual gas flow.

The rotation of the rotor is transmitted via a magnetoresistance sensor from the gas pressurized area to the electronic index which is in the atmospheric environment. The CPU is receiving the high freguency sienal for the maenetoresistance sensor to calculate the gas flow and gas volume under operating conditions. lf the optional electronic volume corrector function is installed the gas flow and gas volume under standard conditions will be calculated according AGA NX-19, The calculation can be based on fixed factors for temperature and pressure or on optionallyinstaled temperature and pressure sensors. The TBQSe is designed to have one external temperature and one external pressure transmitter installed directly in the meter.

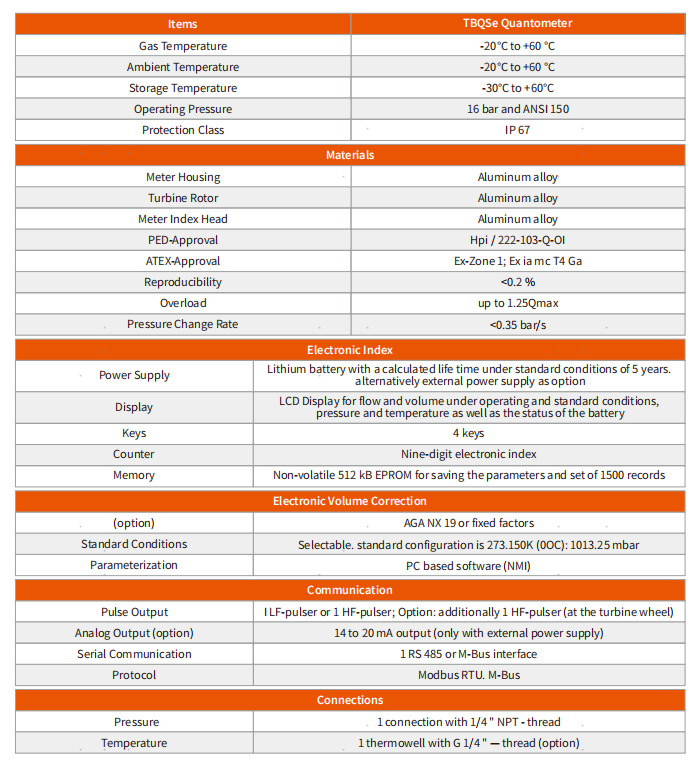

4. Technical Parameters:

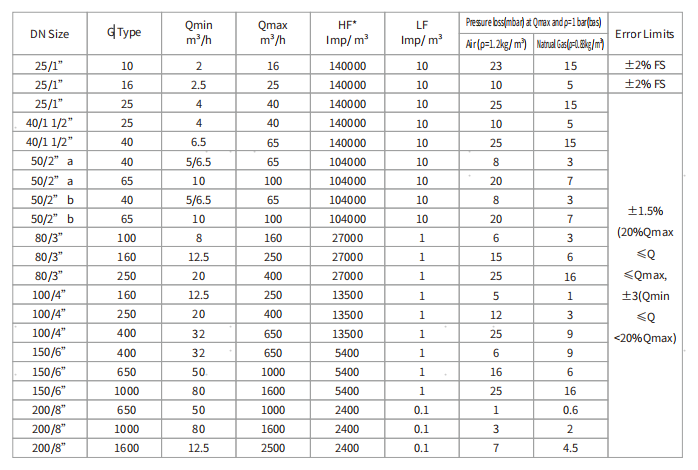

5. Error Limits:

The TBQSe Quantometers are all initially calibrated within the specified measurement errors. Reduced measurement errors limits are optionally available.

The TBQSe Quantometers are manufactured with large measurement ranges due to the precision machining ofthe parts and a reproducible assembly process.

The standard calilbrated measurement range for the TBQSe is 1:20 under atmospheric conditions (exception is the DN25 with 1:10).

6. Sizing Table:

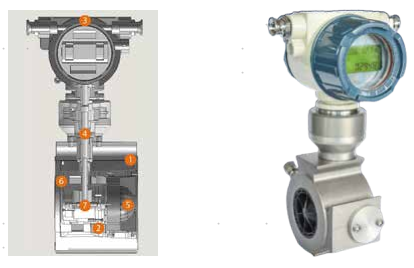

6. Meter Design:

1) Pressure containinghousing

2) Turbine wheel

3) Mechanical counterl index

4) Magnetic coupling

5) Inlet flow straightener

6) Measuring cartridge

7) Gear train

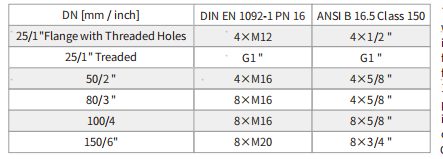

7. Connections:

TBQSe Quantometer housings are manufactured without flanges as a "sandwich" design to be

installed between the two inlet and outlet pipe fanges on a standard basis with raised face (RF)

fanges according to DIN/EN 1092-1 or ANSI B 16.5 for class 150 with a maximum operating

pressure of 20 bar/ 2.0 MPa. The TBQSe DN 25 M'' is designed as flange version with threaded holes or as a threaded pipe version with a thread of G1"